Case Study The Delta Standard is Now Higher

THIRD-PARTY TESTS CONFIRM DELTA CABINETS EXCEED PRESCRIBED AIR EXCHANGE RATES

It is essential for museum staff to find tools that help them offset the environment in which their collections are housed. We take great care to build each of our cabinets because we understand the challenges faced by museum staff.

To ensure they meet your standards, Delta cabinets undergo independent, third-party testing by New York’s Art Preservation Service. APS tests museum cabinetry for air exchange rates by measuring the loss of CO2 in the cabinets. Acceptable exchange rate for cabinetry is 50% CO2 loss over a two-day time period.

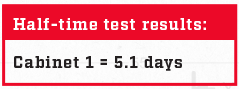

In the most recent testing, Delta cabinets more than exceeded the minimum half-time requirements of one to three days. We are thrilled to share the results of our latest testing.

The Procedure

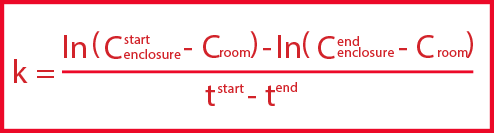

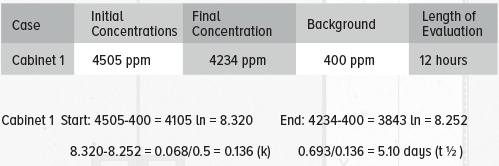

To measure the air exchange rate of the cabinets, 2,500 to 5,000 ppm of CO2 is introduced into each case. The CO2 is measured by a sensor attached to a data logger. The case is sealed and the data logger runs while air in the case is exchanged. Start and end times for the testing were determined by the overall stability of the background CO2. The cabinets were allowed a four-hour window for CO2 equalization before data collection began. The half-life decay of the CO2 within the cabinet was calculated using the slope of the logarithmic graph of the data points collected. Mathematically, the half-time decay is described by the equation below.

C start enclosure = Internal concentration of tracer gas within enclosure at start

C end enclosure = Internal concentration of tracer gas within enclosure at end

C room = External concentration of tracer gas within room

t start = Time at start

The Results

Using the above procedure, APS determined that the Delta cabinet tested exceeded the minimum half-time requirements. The cabinet delivered a half-time decay of 5.1 days. These findings have great implications for the collections stored inside Delta cabinets. Cabinets that remain unopened and secured can exhibit an air exchange rate of more than double the minimum accepted requirement.

Based on these results, Delta cabinets more than exceed the minimum half-time requirement of one to three days!

How We Do It

Delta uses the best available materials and our in-house engineering team to ensure that we deliver the best product on the market. All cabinets are hand welded and hand assembled to guarantee they meet the Delta Standard. Each cabinet is rigidly constructed, from the case to our reinforced 3-point locking doors which creates our industry-leading, hermetically-sealed cabinet. Our attention to craftsmanship and detail results in the optimal air exchange rate for our cabinets.

Why We Do It

Delta Designs is dedicated to creating the standard for museum cabinet storage. We are also dedicated to never settling for less than that standard. The name Delta implies continuous improvement and it is more than a name for us, it is our mission. We will continue to raise the standard for museum cabinetry in order to be the best available partner to collections staff.

What we do matters because what you do matters. We understand the importance of the work undertaken by museum staff every day. Preserving the past helps us ensure the future.

Do you know the air exchange rate of your storage cabinets? Talk to your manufacturer about the performance of the cabinets used to house your collections.

To download a printable version of this case study, click here: